Remote control your Bulk Handling System

RSTAR : Remote System Troubleshooting Automation and Remedy and the Future of Bulk Handling

Your Pneumatic conveying system: The Unsung Hero of Your Plant

Your pneumatic conveying system is the backbone of bulk material handling, quietly transporting raw material powders with minimal maintenance. But that’s precisely the problem—because it requires so little attention, it often gets neglected until something goes wrong. And when it does, the result is costly downtime, panicked engineers, and missed production targets.

Enter R-STAR: The Future of Bulk Handling

R-STAR (Remote System Troubleshooting, Automation, and Remedy) is the revolutionary solution from Scorpio BMH that ensures zero downtime and continuous preventive maintenance. Powered by digital twin technology, R-STAR monitors key parameters online, making real-time optimizations and troubleshooting issues before they escalate.

Why Maintenance Took a Back Seat—Until Now

Before AI, digital twins, and real-time analytics, maintenance was purely reactive—you fixed things when they broke. Pneumatic systems, being inherently low-maintenance, were easy to overlook. But with R-STAR, maintenance becomes proactive, intelligent, and cost-efficient.

Digital Twins: Your Plant’s Virtual Doppelgänger

Imagine having a virtual replica of your pneumatic conveying system that constantly monitors performance, optimizes efficiency, and provides real-time insights. That’s exactly what R-STAR offers.

Key Benefits:

Real-Time Monitoring: Continuously tracks pressure, RPM, flow, level, and temperature.

Early Issue Detection: Identifies potential problems before they cause downtime.

Energy Optimization: Monitors kWh per tonne, ensuring efficient power usage.

The R-STAR Edge: AI Meets Pneumatics

Predict and Prevent Problems

AI-powered sensors track critical parameters.

Immediate alerts and automatic corrections prevent costly breakdowns.

Maximize Energy Efficiency

Real-time energy metrics optimize compressed air and motor power usage.

Actionable insights help reduce operational costs.

Keep Operations Running Smoothly

Automated adjustments ensure peak system performance.

Historical reports provide a comprehensive view of plant health.

How It Works: Smart, Seamless, and Always On

24/7 Real-Time Monitoring: Sensors feed data into R-STAR, which analyzes system performance.

Instant Feedback & Corrections: Automated adjustments maintain optimal conditions.

Comprehensive Reporting: From preventing material blockages to energy optimization, R-STAR delivers the insights you need.

What It Means for Your Industry

Whether you operate in food, chemicals, glass, or paint manufacturing, downtime is the enemy. R-STAR ensures:

Uninterrupted Operations: Stay ahead with predictive maintenance.

Energy Savings: Optimize running costs with real-time data.

Seamless Integration: Works for both new installations and existing plants.

Why Invest in R-STAR?

For New Installations:

Pre-integrated system minimizes costs.

For Existing Plants:

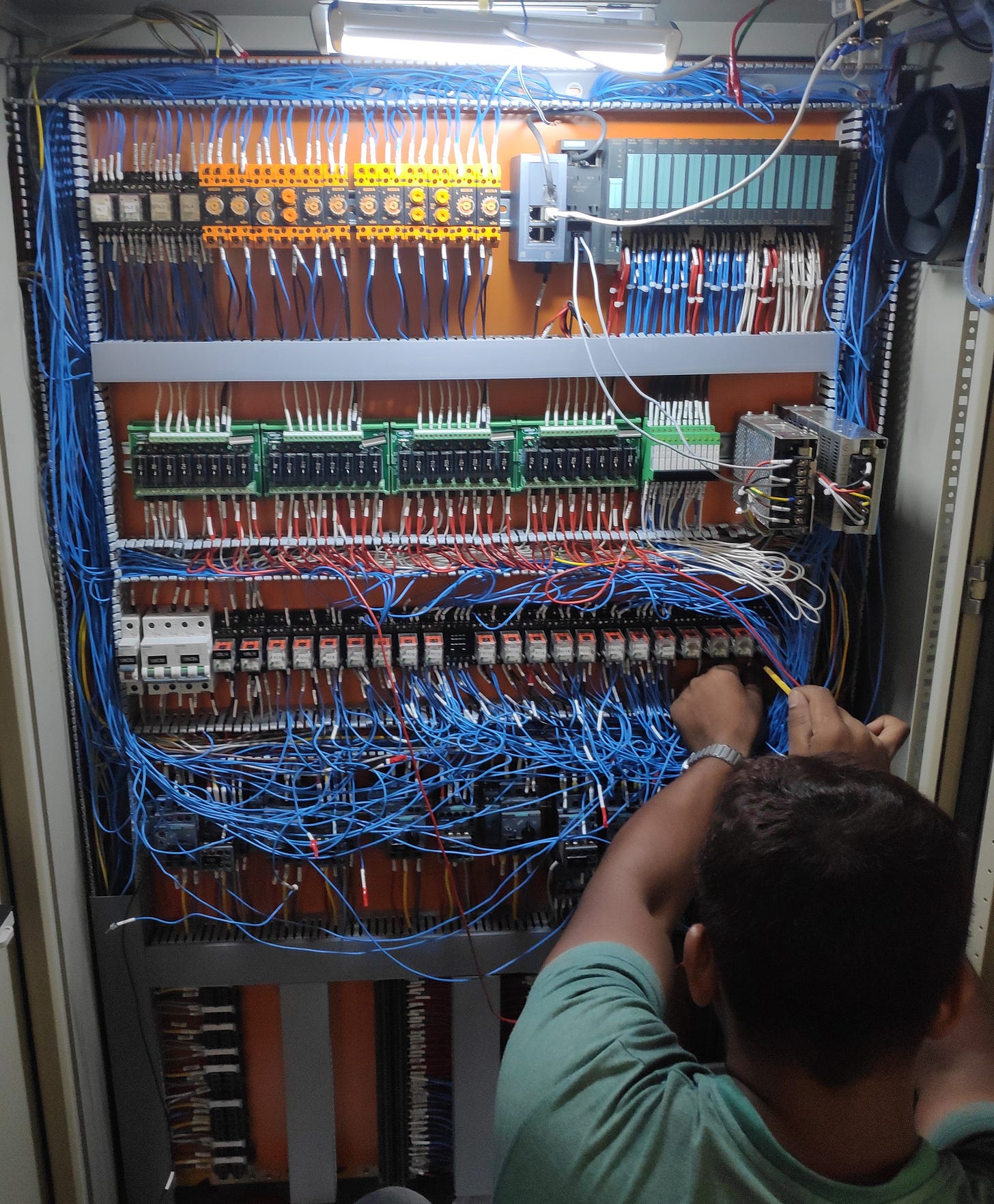

Retrofit options include instrumentation upgrades, SCADA enhancements, and sensor installations.

Costs less than 1% of your original investment—a small price for significant efficiency gains.

Categorized as an OPEX expense, making it budget-friendly.

The Future Is Pneumatic—and Intelligent

The days of “fix it when it breaks” are over. With R-STAR and digital twin technology, your plant becomes smarter, faster, and more efficient. AI-driven automation ensures your pneumatic conveying system receives the attention and optimization it deserves.

Ready to Future-Proof Your Plant?

Buckle up—R-STAR is here to revolutionize your bulk material handling operations. Contact us today to learn how R-STAR can transform your plant into a futuristic powerhouse.